Ozm-120 qhov ncauj qhov ncauj zaj duab xis ua tshuab (lab)

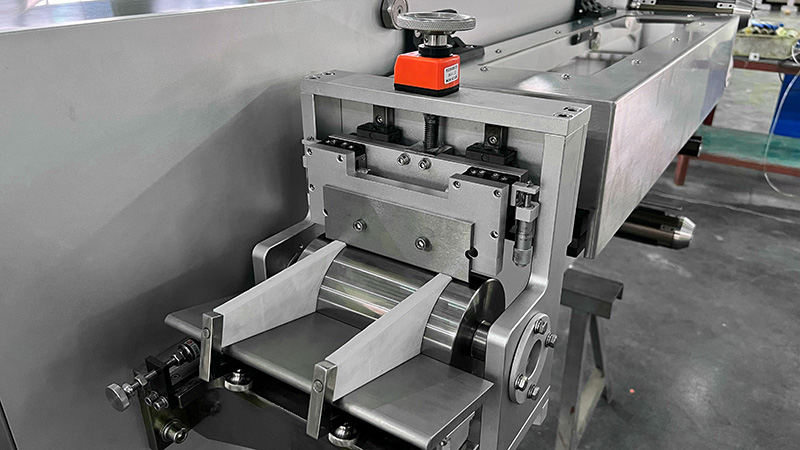

Qauv Daim Duab

Kev piav txog

Qhov ncauj ua yeeb yaj kiab ua tshuab (lab) yog cov khoom siv tshwj xeeb kom ua cov khoom ua kua rau hauv qab kev lamination thiab slitting.

Lab hom Film ua tshuab yuav siv tau rau hauv kws tshuaj, kev lag luam kom zoo nkauj lossis khoom noj khoom lag luam. Yog tias koj xav tsim cov thaj, qhov ncauj soluble zaj duab xis, lub ntsej muag nplaum lossis lwm cov koob hmoov ua zaj duab xis ib txwm ua haujlwm ncaj qha kom ua tiav cov txheej txheem txheej ntau. Txawm tias cov khoom lag luam uas muaj cov qib uas muaj cov kev txwv nruj me ntsis yuav tsum tau siv cov kev txwv nruj yuav siv tau siv peb lub lab zaj duab xis ua tshuab.

Cov tshuab no adopts cov zaus converter rau kev tswj cov hluav taws xob nrawm, hluav taws xob, hluav taws xob ua kom haum GMP qauv thiab ultricful.

Nrog nws txoj haujlwm ntawm zaj duab xis ua thiab ziab, tswj los ntawm PLC panels, nws yog ib qho yooj yim rau khiav. Txhua qhov kev txhawb nqa kev pab, thiab cov tom qab muaj xws li kev ua haujlwm hauv cov neeg siv khoom.

Kev Ua Tau & Nta

1. Nws yog qhov haum rau cov ntawv tsim kev sib xyaw thiab cov yeeb yaj kiab ua yeeb yam. Lub zog siv hluav taws xob ntawm tag nrho cov tshuab adpts servo tsav ceev txoj cai kev cai. Unwinding prints sib nqus hmoov nres nro tswj.

2. Cov khoom siv muaj cov ntaub ntawv ua haujlwm ntev thiab ua kom ceev.

3. Lub qhov cub qhuav adopts cov qauv cua sov hauv qab ntawm lub tiaj tiaj, thiab qhov ntsuas kub yog tswj tau los ntawm PID, thiab kev tswj hwm qhov raug tuaj yeem ncav cuag ± 3 ℃.

4. Lub chaw sib kis tau tom qab thiab cov haujlwm ua haujlwm hauv pem hauv ntej, uas zam rau ntawm ob qho chaw thaum cov khoom siv ua haujlwm, thiab yooj yim dua kom huv.

5. Txhua feem hauv kev sib cuag nrog cov khoom siv, suav nrog nias chais thiab cov khoom siv tsis muaj zog thiab cov khoom siv dag nrog cov kev cai thiab cov kev qhia tshwj xeeb ntawm "GMP". Txhua lub Cheebtsam hluav taws xob, xaim thiab cov qauv kev khiav haujlwm ua raws li "ul" "tus qauv kev nyab xeeb.

6. Cov cuab yeej siv thaum muaj xwm ceev nres ntawm cov cuab yeej txhim kho kev nyab xeeb ntawm cov neeg ua haujlwm thaum debugging thiab hloov hloov.

7.

Lub ntsiab kev tsis sib xws

| Yam | Chaw ua uas tsis tau haus |

| Siv tau qhov dav dav | 120mm |

| Yob dav | 140 hli |

| Neeg kho tshuab ceev | 0.1-1.5m / min (Nyob ntawm cov khoom siv tiag tiag thiab xwm txheej) |

| Unwinding inch | ≤ renn150mm |

| Rewinding hla | ≤ renn150mm |

| Cua Sov Drying Txoj Kev | Phaj Cua Sov, Centrifugal Ntxuam Kub Cua Sov Cua Sov |

| Tswj Qhov Kub | Chav Chav Chav: -100 ℃ ± 3 ℃ |

| Reel ntug | 3.0mm |

| Tag Nrho Fais Fab | 5kw |

| Qho loj | 1900 * 800 * 800mm |

| Qho hnyav | 300Kg |

| Fai fab hov ntau | 220V |